What are Quality Costs ?

Quality Costs

Quality costs or Cost of Quality (COQ) are the costs associated with the Quality related efforts by Organizational personnel. Every Organization puts a certain level of effort in maintaining the Quality level that it claims for its products and services or that meet the expectations of its Customers. These costs are called Quality Costs. An American Quality Control expert called Armand V. Feigenbaum first introduced this concept of cost of Quality in the year 1956 in a Business Management article.

Quality costs or Cost of Quality (COQ) are the costs associated with the Quality related efforts by Organizational personnel. Every Organization puts a certain level of effort in maintaining the Quality level that it claims for its products and services or that meet the expectations of its Customers. These costs are called Quality Costs. An American Quality Control expert called Armand V. Feigenbaum first introduced this concept of cost of Quality in the year 1956 in a Business Management article.Till this concept was introduced, Financial personnel did not think that there can be costs associated in maintaining the Quality level in an Organization. It was an eye opener to understand that “Quality also costs”.

What are the types of Quality Costs?

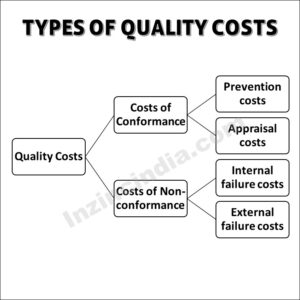

Armand Feigenbaum has identified the costs of Quality as shown in the figure. According to Feigenbaum, there are two major categories of Cost of Quality:

Costs of Conformance: Costs of Conformance are costs to ensure conformance of products and services by controlling them, and is sub-divided into:

Costs of Conformance: Costs of Conformance are costs to ensure conformance of products and services by controlling them, and is sub-divided into:

- Prevention Costs: These are costs that are incurred to prevent non-conformance from happening. Examples include Cost of training personnel on Quality requirements, Cost of planning for Quality, cost of implementing Statistical Quality Control techniques, development of Quality systems and costs associated with its sustenance, etc.

- Appraisal Costs: These are costs that are incurred to ensure the conformance through measurement and monitoring. Examples include audits, inspection, testing, calibration etc. Testing can be acceptance testing, field testing or testing of materials.

- Costs of Non-conformance: Costs of Non-conformance are costs incurred in the event of failure of controls and is sub-divided into:

- Internal Failure Costs: These are costs that are incurred because of failure of products and services and is observed before shipping the products to the Customer or before delivering services to the Customer. Examples include cost of producing defects, cost of scrapping, cost of rework, cost of repair, cost of re-design, cost of downtime, cost of time spent in sorting the scrap, etc.

- External Failure Costs: These are costs that are incurred because of failure of products and services and is observed after shipping the products to the Customer or after delivering services to the Customer. Examples include cost of complaints under warranty, cost of complaints after warranty period, cost of recall of the product, cost of returns, cost of loss of brand reputation, cost of penalties from Customers, cost of liability or lawsuit, etc.